Our products are developed, designed, and manufactured under one roof to ensure on-time delivery with all customer requirements met. Our thorough maintenance regime has also earned high trust from users at home and abroad, bringing us recognition as the world-standard Kitagawa Engineering Brand. We continue our efforts to further improve our technical competence so that we can continuously serve customer needs with products and system proposals.

Plywood production systems

-

Plywood production line

-

Plywood production line

-

Plywood production line

-

Direct system for plywood production press without pre-pressing

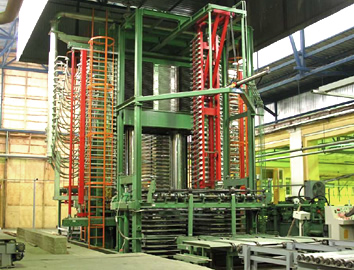

Plywood press machinery

-

Plywood hot press

Product size: 5'×10'

Number of press openings: 30 -

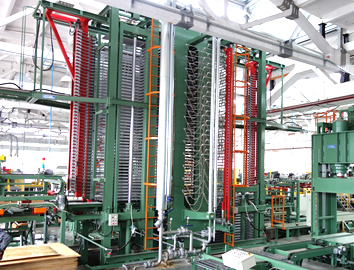

Plywood hot press

Product size: 5'×5'

Number of press openings: 50 -

Plywood hot press

Product size: 4'×8'

Number of press openings: 42 -

Pressing system for phenolic film

-

Cold press

Plywood machinery

-

Rotary Lay-up machine

(automatic veneer lay-up machine for plywood) -

Pairing machine

(automatic veneer pairing machine for plywood) -

Pairing machine

(automatic veneer pairing machine for plywood) -

Automatic veneer/panel feeder

Other equipment

-

4'×20' hot press for glued laminated timber/CLT

(high-frequency heating type) -

Dehydrate press

(for green veneer) -

8'×16', 3000 tons,

single-opening hot press